In April 2008 The Liberty Science Center, a 295,000 square foot educational science center for the general public, installed Noveda Technologies SunFlow Monitor™ and EnergyFlow Monitor™ to optimize the facility's newly installed solar photo voltaic system.

SunFlow Monitor™ records and displays in real-time all electrical energy coming into the building from the grid, electrical energy going out from the building to the grid, electrical energy consumed by the building, and electrical energy produced by the solar photo-voltaic system.

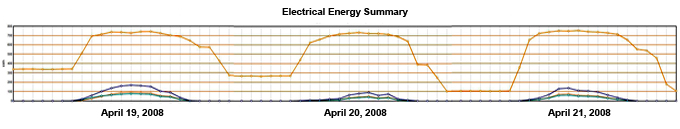

After the first night in use, SunFlow Monitor™ data showed that the facility was consuming three times more energy during the night than originally estimated. Between the hours of 10:00 pm and 6:00 am The Liberty Science Center was consuming unnecessary electricity to run the air conditioning, lighting and other energy intensive systems of the building.

Because of the instant feedback, facility operations staff at Liberty Science Center discovered that the air handling units were running in occupied mode during the night, bringing hot, humid air into the building. By readjusting the night settings, daily electrical consumption was reduced by approximately 11.5%. It was estimated that this problem was occurring for the past year, costing an average of $5,800 per month or nearly $70,000 per year! In terms of the environmental impact, the energy savings resulted in daily reductions of 1.24 metric tons of CO2 greenhouse gases. Noveda's technology offered a three month payback on their investment.

Overall, installation of the SunFlow Monitor™ resulted in an immediate daily electrical savings of 11.6% and a significant reduction in greenhouse gas emissions.

For more information about this project and other Noveda projects please visit www.noveda.com

For more information about Liberty Science Center please visit www.lsc.org

Attached to 31 Tannery’s standing seam metal roof are 1,276 solar photovoltaic panels. Being new construction, rooftop penetrations and systems, such as the rooftop unit (RTU) and shop ventilation system, were kept to the north side of the building to maximize performance of the rooftop solar photovoltaic array. The solar electric system produces on average 500 kWh per day in the winter and 1,300 kWh per day in the summer. On a cloudy or overcast day, the combined inverter output typically measures 30–40 kW ac. On a sunny day, design conditions of 200 kW ac have been reached.

Attached to 31 Tannery’s standing seam metal roof are 1,276 solar photovoltaic panels. Being new construction, rooftop penetrations and systems, such as the rooftop unit (RTU) and shop ventilation system, were kept to the north side of the building to maximize performance of the rooftop solar photovoltaic array. The solar electric system produces on average 500 kWh per day in the winter and 1,300 kWh per day in the summer. On a cloudy or overcast day, the combined inverter output typically measures 30–40 kW ac. On a sunny day, design conditions of 200 kW ac have been reached.